With over 50 years of experience providing first-rate support to the contract packaging industry, SPS has a reputation as the go-to packaging source for large and small operations. However, we are not just any supplier – we are a value-added shipping partner you can trust to optimize your contract packaging operations and profits. To us, delivering The Whole Package is not just a tagline – It’s a bottom-line promise. Factoring in savings on shipping strategies is an important part of the equation, and this blog will detail three (3) strategies and accompanying opportunities that SPS utilizes to assist our valued clients.

Contract Packaging to Boost Profitability

Ultimately, SPS helps to enhance your profit margins by offering the lowest prices per packaged unit on our contract packaging materials. How do we do this?

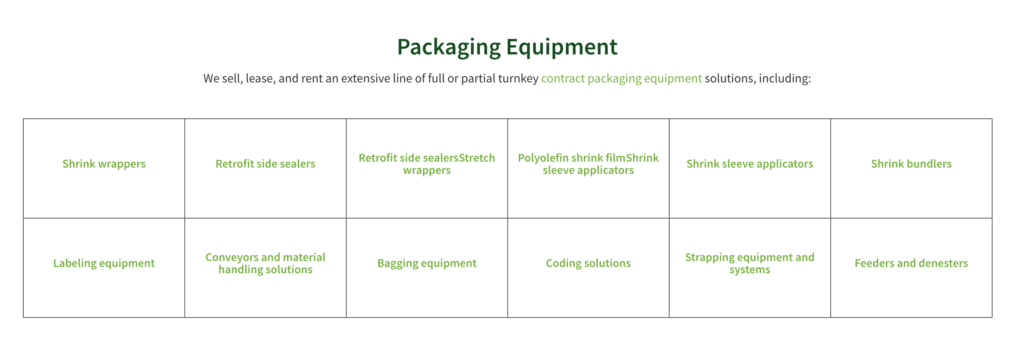

- By providing affordable and effective contract packaging materials and equipment.

- By offering a robust line of contract packaging materials from industry-leading suppliers

- By selling, leasing, and/or renting our customers an extensive and high-quality line of contract packaging equipment solutions – always with your budget parameters in mind.

In addition, we have cost-effective shipping rates. When coupled with the budget-friendly equipment purchase, lease, or rental options noted above – we can help our clients to achieve their fiscal goals. Learn more here about this component of the SPS business solution.

Shipping Solutions that Work for Your Company.

Once products have been packaged via SPS’s industry-leading processes, promptly and efficiently delivering them to the market is of critical importance. SPS has a rich history of working collaboratively with companies that range in size from multi-national corporations to small businesses that are either well-entrenched or just getting started. We are always happy to work with you to remain within budget by helping you to craft various shipping alternatives that will not sacrifice the quality of your product. Additionally, our representatives are experienced at working with shipping companies to find the best possible options and carriers to deliver your packaged products to the appropriate destinations – on time and within your budgeted parameters. Some strategies we use as we work with our clients on shipping considerations:

- Single vs. Multiple Carrier Engagement. In many cases, a single carrier is the best shipping option due to a negotiated, flat rate fee for all products being delivered to their destinations. However, we have found that in some instances it is better – and more economical – to engage multiple shipping companies. Our team is highly experienced at helping our clients to determine the best shipping strategy for their needs.

- Shipping Frequencies. When possible, consolidating multiple orders into a single shipment can reduce individual shipping costs and increase efficiency.

- Routinely Reevaluate Shipping Zones: We encourage our clients to assess shipping zones periodically to ensure the most cost-effective shipping options based on your customers’ locations and needs.

Package Design and Optimization

Efficient packaging can significantly reduce shipping costs. Choosing packaging that is customized to your products and eliminating excess space and weight will decrease shipping costs. To enable these efficiencies, SPS has a team of professionals involved in the various components of the process:

- It all Starts with Design! During the packaging engineering and design process, our industry-leading packaging and mechanical engineers will work collaboratively with you. Together, we will identify the best materials, system designs, and automation for your contract packaging needs – while always keeping the critical factors of product logistics, load containment, sustainability, and marketing at the forefront of our thinking. Additionally, the SPS expert graphic design packaging experts will provide graphics and art support to ensure that your package stands out.

- Material Selection. The material that a manufacturer chooses to use in its packages can affect its ability to remain competitive. Material advances, equipment technology, transportation efficiency, and other positive trends have spurred creative turnkey packaging solutions matched to the needs of modern producers.

- A Technical Sales Approach. One of our founding principles continues to guide our mission today: all companies (large and small) can benefit from the technical capabilities of their packaging vendors. This is attained via choosing the right materials, system designs and automation. To support this mission, SPS has – and shall continue to – focus on hiring the best and brightest packaging and mechanical engineers.

Determining Factors for Shipping Partners

Overall, this blog has explored three strategic approaches that SPS utilizes as we work with our clients to not only provide world-class packaging solutions and services, but also explored approaches to conserve resources within the important shipping component of the overall process. It is important to bear in mind that shipping costs can vary based on your specific business needs, location, and shipping volume. Implementing the tips shared in this article can help you stretch your savings, improve your shipping efficiency, and positively impact your bottom line.

With a rich history of successfully meeting – and exceeding – client expectations, SPS is ready to work with your business. Contact us to get the process started!

“Get to know SPS. You’ll understand why we are the Whole Package!”